Traditional LEDs have been useful for indication and exhibit purposes for several decades. The natural benefits of LED technology are well-known and reported, and contain, maintenance and energy savings, in addition to performance functions which can be taken for given by electronics-savvy consumers such as for example longevity, reliability, longer expected life, and consistent shade and perfection levels. These benefits, along with society’s growing environmental issues and subsequent need for green, energy-efficient services and products, have continued to drive the growth of LEDs for tough new industries and areas, such as standard light for professional and residential buildings.

With the escalating demand for solid-state illumination, LED companies are motivated to develop high-lumen LEDs while LED light businesses will work difficult to incorporate the newest technology into retrofit offers and luminaries. But, new sides may be required for visitors to undertake LED technology as an light resource in new installations, or integrate LED engineering in present mild fixtures.

Professional and residential light programs stand to achieve similar, if not more, energy-savings by changing to LEDs. However, most applications are not as straight-forward as padding a PC panel with a lot of directional red, amber or natural LEDs. LED mild fittings and retrofit offers have to be made to distribute the directional gentle developed by the LED over large areas.

Moreover, bright LED technology, while continuously improving, does not even have the visual shade and illumination that people have grown to be used to with incandescent lights. But, the energy savings can be significant, as an example, in Colorado the energy commission has used performance criteria for residential and industrial buildings. These criteria, Subject 24, have accelerated development of LED light technology.

Unlike incandescent bulbs, high-power LEDs cannot be just plugged into a wall socket. Several organizations work to over come the technological and financial difficulties by creating LED mild fixtures and retrofit LED lighting products and services applying high-power LEDs. Thermal administration, complicated travel circuitry, optics, and appearance are difficult hurdles for designers to contend with.

Additionally, there are educational barriers to overcome in the growth of professional LED illumination products. Finding consumers to undertake new forms of fixtures, realize the light features of LEDs, choose the appropriate viewing position for certain application, select the right intensity for confirmed program, and understand the limits of LED shade conditions are vital to creating the marketplace for LED technology in professional and residential lighting.

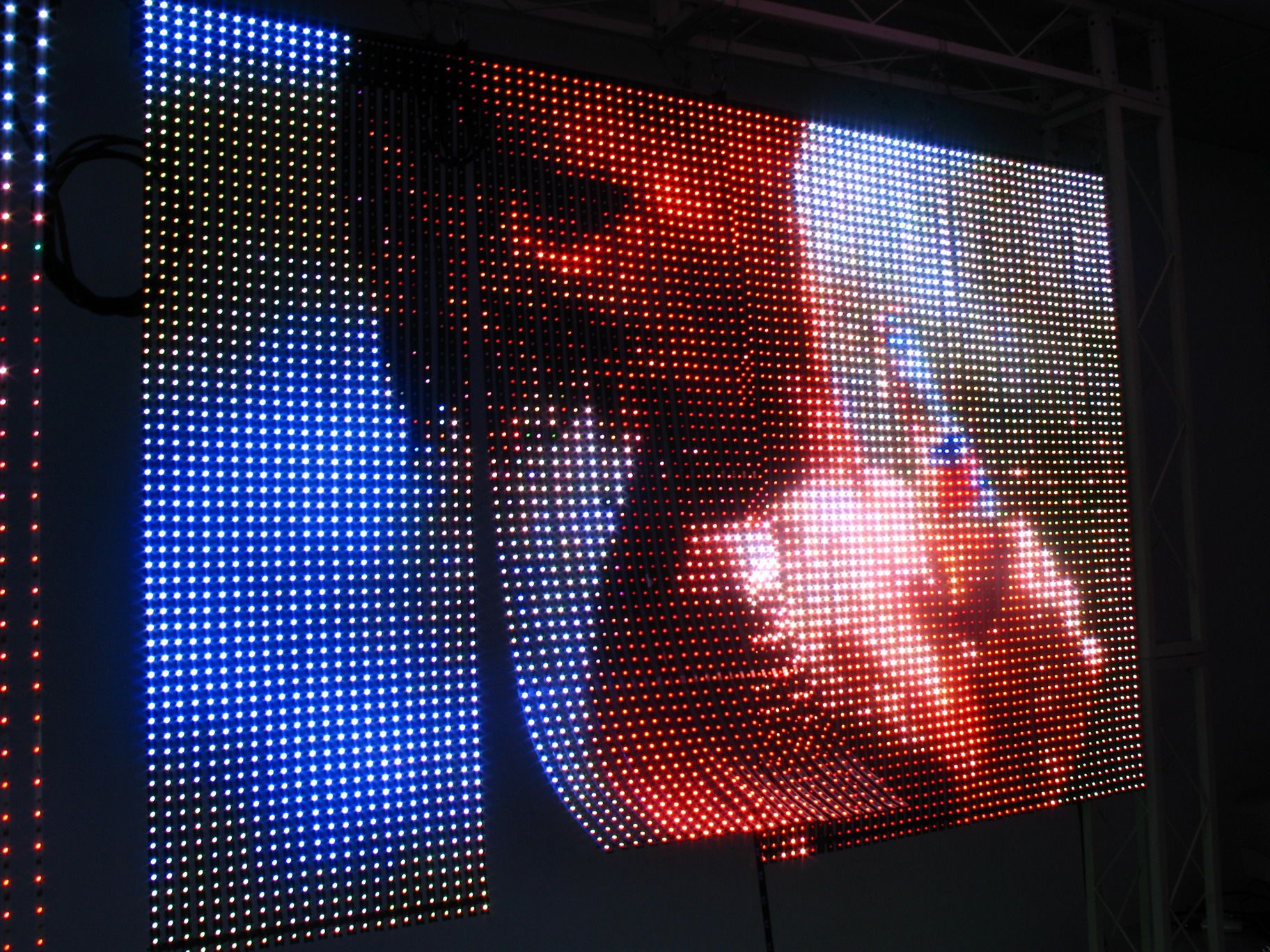

For yesteryear couple of generations, standard luminaries have contained a light bulb and light socket that permits people to continually replace lamps which have burnt out. Whether it is an incandescent, lightweight fluorescent or fluorescent lamp, it will simply screw or drop in to an industry-standard socket and the luminary may continue to be operational. A few led display light businesses have developed high-flux LED bulbs that retrofit in to active sockets; but this approach is significantly less than ideal.

Like, a normal light bulb socket supplies a very poor thermal course for chilling an LED light source. Incandescent gentle lamps are generally heaters that creates obvious mild, and the socket it is screwed in to is made to protect the light foundation and wiring from that heat. With high-power LEDs, most of the wattage consumed is converted to temperature and, if it can’t be dissipated through the lamp socket, may considerably shorten the LED life.

To protect the LED from destruction factors, such as heat and voltage spikes, the drive circuitry design is critical. Preferably, LED signal patterns should really be tailored to the details of the application since mechanical and financial constraints make it hard to design a “catch-all” circuit. Many LED sign or illumination models run from a top voltage AC power source. Because LEDs are DC-driven, utilizing a particular AC to DC power supply to reach a DC supply voltage is often the many cost-efficient and reliable LED illumination solution.

To ensure successful LED function, DC-to-DC LED driver circuitry are often expected in conjunction with the primary energy supply. In addition to giving the necessary energy and security from recent variations, LED get circuitry also produces temperature – contributing to the thermal management challenge. And, usually, the higher the quantity of mild that is expected, the more LEDs are essential, ultimately causing more complex the circuitry, presentation challenges, larger temperature flux, etc.